Knit vs. Woven Fabric: for Supply Chain Professionals

April 15, 2025 | Resources

Let’s be honest—fabric doesn’t always get the spotlight. But if you’re working anywhere near the apparel supply chain, understanding the difference between knit and woven fabrics isn’t just helpful—it’s a game-changer.

From sourcing smarter to negotiating like a pro, knowing when and why to choose one over the other can save you time, money, and a lot of efforts.

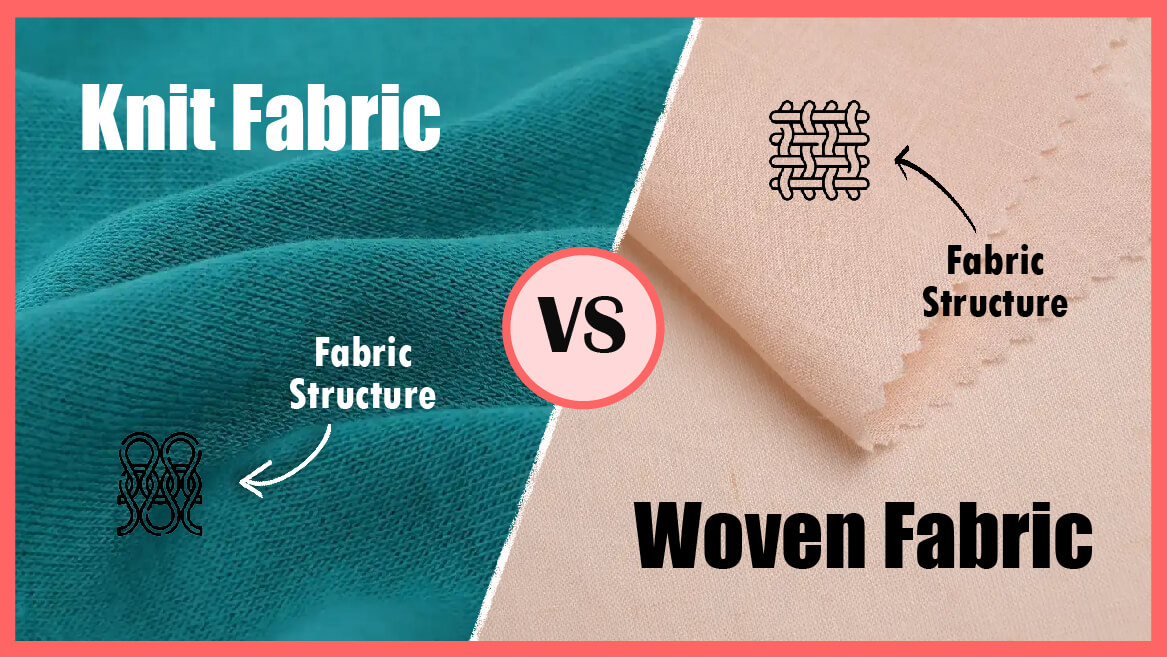

What’s the difference between knit fabric and woven fabric?

Knit fabric

The actual difference between knit and woven fabrics lies mainly in their structure and properties. Knit fabrics are made by interlooping yarns, resulting in a super stretchy, forgiving material with excellent breathability, making it perfect for outdoor activities. They are commonly used in casualwear and activewear due to their soft, flowy drape and moderate durability, which supports easy movement. Production is also fast, thanks to efficient circular knitting machines.

Woven fabric

In contrast, woven fabrics are created by interlacing yarns, giving them a strong, structured form with little to no give. They offer good breathability depending on the design and are often used for button-down shirts, tailored trousers, formalwear, uniforms, and outerwear. Woven fabrics drape in a crisp, clean, tailored way, are highly durable, and are ideal for long-lasting garments. Although the production process of woven fabric is slower because weaving looms are more time-consuming.

Should you choose knit fabric or woven fabric?

This is where things get interesting. The answer? It depends. Let’s break it down.

Fashion & Apparel: Comfort vs. Structure

- Knit fabrics are meant for casualwear, activewear, and anything that needs to move with the body. Think loungewear, tees, yoga pants.

- Woven fabrics should be your choice if you want structure and form. Blazers, button-downs, tailored trousers—they’re all about clean lines.

Pro tip: Want structure with a bit of stretch? Go for stretch wovens with elastane. Best of both worlds.

Industrial & Uniforms: Strength vs. Mobility

- Wovens win on durability. If you need something that holds up to tough work environments, they’re your friend.

- But technical knits are catching up fast—especially in uniforms where comfort and mobility matter. Polyester blends, moisture-wicking features… the list goes on.

Speed to Market & Minimum Order Quantity (MOQ)

- Need things fast or in small batches? Knits are more flexible—literally and logistically.

- Wovens usually come with higher MOQs and longer lead times—but they deliver on quality, especially for premium or luxury pieces.

E-commerce & Direct to Consumer Market

- Online shoppers gravitate toward comfort and knit often outperform woven in return rates and customer satisfaction because they conform more easily to various body types.

- For luxury or statement pieces, wovens offer weight, texture, finish and convey status.

There’s no universal winner in the knit vs. woven debate—but there is a right fabric for every product and every purpose.

As supply chain professionals, knowing the difference isn't just trivia—it’s strategy. It helps you speak the language of designers, meet market needs faster, and build smarter product lines from the ground up.

At Threadify, we help brands make confident, informed sourcing decisions—whether it’s buttery-soft jersey knits or crisp, high-end shirting.

Empty Cart

Empty Cart